In many cases, we only need small quantity plastic parts for some purposes, such as market trial, products function test etc. Which we have to save the mold cost and lead time, then the prototype molds would be the best choice,

Prototype molds are usually built to last a short life. The mold is built without features found in the production mold, so the build time is less and the mold less expensive.

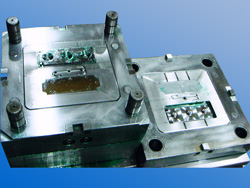

A prototype mold is similar to a production mold. It can be single cavity as shown above, or make more than one part, called a family mold; The main advantage of using a prototype tool is time and cost. If you are not 100% sure the part you are designing will work, then it is better to build a single cavity prototype mold instead of starting with the production mold. The cost to make changes to a single cavity mold is far less than modifying a multi-cavity, heat treated mold.

-Quotes in 12 hours, typical

-Volume: 100 to 100, 00 parts

-Tyical mold cost: $2500-$9000, typical

-No. Of Cavities: 1 to 4 cavities, or more

-Lead time: 2 to 5 weeks for parts

Prototype molds are usually built to last a short life. The mold is built without features found in the production mold, so the build time is less and the mold less expensive.

A prototype mold is similar to a production mold. It can be single cavity as shown above, or make more than one part, called a family mold; The main advantage of using a prototype tool is time and cost. If you are not 100% sure the part you are designing will work, then it is better to build a single cavity prototype mold instead of starting with the production mold. The cost to make changes to a single cavity mold is far less than modifying a multi-cavity, heat treated mold.

-Quotes in 12 hours, typical

-Volume: 100 to 100, 00 parts

-Tyical mold cost: $2500-$9000, typical

-No. Of Cavities: 1 to 4 cavities, or more

-Lead time: 2 to 5 weeks for parts

Main Products

plastic injection molding,CD Tray mold,unscrewing mold,over molding